Lightweight, durable, FEA tested carbon fiber Reflectors and subreflectors. Our component designs are crafted in-house with precision to ensure maximum efficiency and a prolonged lifespan.

[ jump to ]

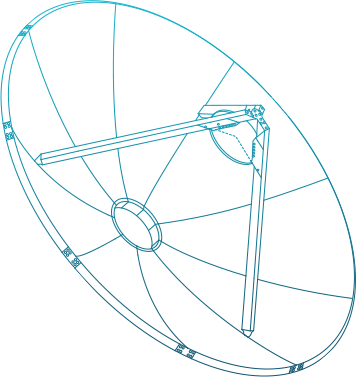

CGC signature carbon fibre Reflectors are lightweight, durable and exceptionally efficient. Once moulded they are inspected via photogrammetry, ensuring a perfect metalized surface with an accuracy of 0.1mm.

We choose carbon fiber over aluminium, which is typically used to build relfectors. Carbon fiber is more light weight and yet stronger than its counterpart, reducing the power needed to move it parabolically and simultaneously withstand greater physical obstacles.

Coefficient Thermal Expansion Comparrison:

Carbon Fiber: <2×10-6

Aluminium: 23×10-6

Carbon fiber Reflectors come with the added benefits of corrosion resistance and superb thermal conductivity, (allowing Antennas to thaw quickly in very cold environments). This helps to prolong the lifespan of the final Antenna, which is exceptionally important to our customers.

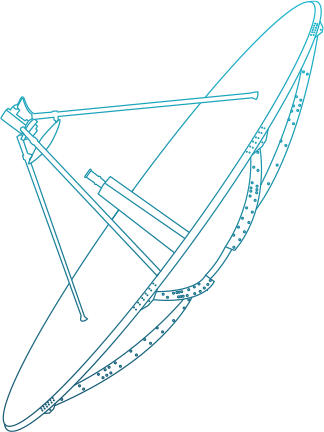

For systems including a Cassegrain feed, the required reflector is dual shaped and operates with a sub-reflector. This can produce very high performance by controlling the reflector edge taper and reducing the central (blocked) illumination.

Greater system efficiency can be obtained by reshaping the hyperbola of the subreflector to change the taper at the dish edge to be sharper and by making the centre of the reflector more pointed, therefore removing the hot spot. This increases the system efficiency significantly. A small change in the reflector shape away from true parabolic restores phase coherency and retains the system efficiency gains.

Composite subreflectors, which are fitted to cassegrain systems, are stiff, strong, lightweight and very temperature stable. Dimensional stability of the sub-reflector is more important than the main reflector and is produced to a surface accuracy of 0.03mm.

The carbon fibre petals are individuay cast and equally segmented, ensuring ease of installation and interchangeability if any become damaged in the field. In fact, we have been known to make repairs without taking systems off-line or affecting performance. Although these types of events are extreamly rare, we must ensure our customers are safe-guarded if they need to prepare for problematic environments.

There are no limits on the size of reflector we can produce due to having our own facilities for design and manufacture.

Heater elements can be embedded in the front reflector surfaces to prevent icing. Due to the very low thermal expansivity of carbon fibre there is no shape change with temperature. This system is controlled via the ambient temperature panel and can be set by our customers to adapt to the environment.

Our Refelctors are manufactured at the highest possible quality and in such a way that offers an attractive price point, particularly in large volumes. We keep control of unit quality by undertaking rigorous testing, including photogrammetry.

Photogrammetry is a non-contact measuring system. The set up is similar to motion capture. It is capable of measuring large volume assemblies with categorical accuracy.

The process is used to validate parts during the manufacturing process and to align all parts of the system [ inlcuding the reflector surface, subreflector and feeds ]. This ensures no extra site photogrammerty is necessary before delopyment of systems, rapidly speeding up the installation process.

Comtech Ground Systems UK Office

1 Beechwood, Chineham Business Park,

Lime Tree Way, Chineham, Basingstoke, Hampshire RG24 8WA, UK.

Comtech Ground Systems US Office

6181 Chip Ave. Cypress, CA, 90630, USA.

Tel: +44 (0)1252 724274 (UK)

Tel: +1 310 214 5500 (USA)

sctsales@comtech.com

FIND US: Comtech Ground Systems, 1 Beechwood, Chineham Business Park, Lime Tree Way, Chineham, Basingstoke, Hampshire RG24 8WA.